Safety Performance Management is a key requirement for a functioning SMS. Implemented properly, it will give management an indication of how the business and its processes are performing in terms of meeting its safety objectives. Furthermore, the safety information provided will enable management to make informed and robust, data driven decisions. This is achieved through the identification and monitoring of SPIs that are (ideally) linked to the organisation’s safety objectives.

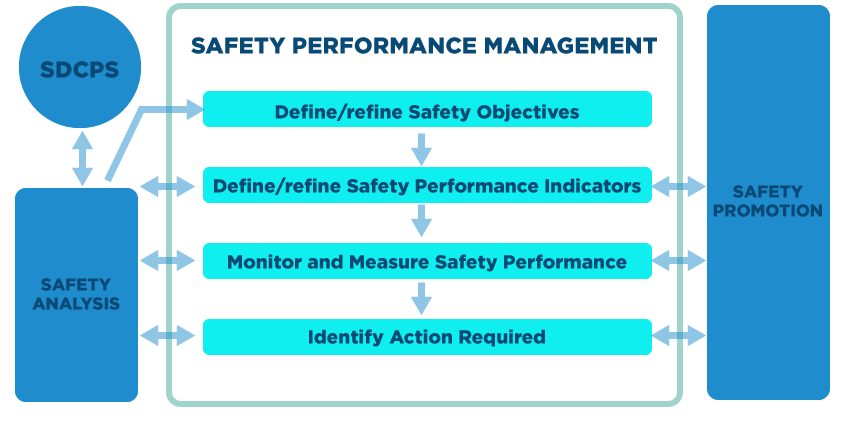

The diagram below (source: ICAO Document 9859) shows how safety performance management fits within the overall SMS of an organisation.

In order to achieve effective safety performance management, safety data has to be gathered, sorted, stored and recovered via the Safety Data Collection and Processing System (SDCPS). This data is turned into useful safety information by completing various processing and analysis tasks, part of which is the recovery of useful information to determine whether or not the various SPIs are on track to meet their respective targets.

Safety promotion is a key element in this overall process. Unless the entire workforce is informed and engaged in the management of safety, there is a high likelihood that voluntary reporting rates will be low, and management will not have a full picture of the risk landscape posed to their operation. Furthermore, if there is a paucity of reports being submitted, there is little opportunity for the safety team to determine the performance of the defined SPIs, hence, management will struggle to determine if the business safety performance is achieving its stated goals.

A well-developed safety performance management structure will enable the organisation to answer the following, originally coined by William Voss (past CEO of the Flight Safety Foundation).

Let me ask you four simple audit questions that are easy to answer if you have an effective SMS but are virtually impossible if you have not:

- What is the most likely cause of your next serious safety event?

- How do you know that?

- What have you done about it?

- Is it working?

The definition and monitoring of SPIs has already been covered in detail in previous articles; however, this important aspect of your SMS relies on the implementation of effective safety data collection and processing.

Safety Data Collection and Processing

A quotation often stated is that many airlines are ‘data rich but information poor’. By this we mean that most airlines will have in place a process to collect safety data (i.e. what is reported, observed or measured by observation). However, this data must be analysed, processed and organised, within a given context, to turn it into useful safety information that can be used effectively for the management of safety.

The management of safety is highly dependent on the effectiveness of safety data collection, analysis and overall management capabilities. Having a solid foundation of safety data and safety information is fundamental for safety management, since it is the basis for data-driven decision-making. Reliable safety data and safety information is needed to identify trends, make decisions and evaluate safety performance in relation to safety targets and safety objectives, and to assess risk.

Clearly, each organisation will have differing requirements and priorities when it comes to safety data collection. Identifying and collecting the safety data should be aligned with the organisation’s need to manage safety effectively.

Safety data can be derived from a number of disparate sources and is not just confined to the safety reporting system. In the case of an airline, the following sources of safety data may be utilised (this list is not exhaustive):

- Mandatory Occurrence Reports

- Voluntary Reports

- Flight data analysis

- Fatigue risk analysis system

- Human Factors Analysis and Classification

- Recorded data (FDR, CVR)

- Risk Register

- SPI Trend analysis

- Internal and external audit reports

- Pilot records

Data quality relates to data that is clean and fit for purpose. Data quality involves the following aspects:

- Cleanliness

In simple terms, inaccurate or corrupts data is useless.

- Relevance

Only data that meet an organisation’s needs should be preserved.

- Timeliness

Data used for should reflect what is happening as close to real time as possible. Judgement is often required based on the volatility of the situation.

- Correctness

Data accuracy refers to values that are correct and reflect the given scenario.

Focused data fusion is essential

The real skill required is to store and integrate all of the disparate data sources and then apply relevant processing techniques to produce robust information that can be presented to management so that they can then make defensible, data driven safety decisions.

The idea of data fusion is relatively new, and it is really the next step in the data transformation process. Often referred to “big data” it is the integration of a number of data sources (not all of them owned by the airline) in a common format that will enable the safety team to conduct deeper trend analysis.

An example might be the use of weather data alongside FDM and air safety reports. When combined, these three data sources might indicate hitherto unseen trends; for example, a pattern in the occurrence of unstable approaches.

Summary

As with a fully functioning and effective safety management system, effective safety performance management relies upon the dedication and expertise of those involved. In particular the management of safety data and information is a difficult process and ideal candidates for this role must have excellent data analytic skills. In addition, they will require good interpersonal skills such that they gain the trust of the workforce. This combined with a supportive safety reporting culture will have an exponential effect upon the safety and compliance of an organisation.

To obtain a free guide aimed at supporting an airline’s safety culture take a look at The Essential Guide to Aviation Safety Management systems – Download our free insight